3D Printing Service

Professional rapid prototyping 3D printing service.Whether it's precise SLA 3D printing, durable SLS 3D printing, or even metal SLM printing, you can perfect your designs without limits.

What Is 3D Printing Prototype?

3D printing is a broad term used to describe additive manufacturing and includes a variety of rapid prototyping technologies that combine multiple layers of material to create parts.

Rapid prototyping 3D printing is a fast, easy, and affordable way to turn great ideas into successful products. These 3D-printed prototypes not only help validate designs, but they also help catch problems early in the development process, provide direct feedback for design modifications, preventing costly changes once the product is in full production.

Why Choose Betly For 3D Printing Service?

Betly is an expert in the field of rapid prototyping manufacturing, offering a wide range of 3D printing services, including SLA 3D printing, SLS/MJF 3D printing, SLM metal 3D printing, FDM 3D printing.

Betly has a full team of dedicated engineers and project managers to work with you to review CAD designs, product features, dimensional tolerances, and more. As a prototyping company, we fully understand the prototyping and production needs of all companies.We strive to deliver affordable, quality-assured products to our customers around the world. We strive to meet all specified times.

Benefits Of 3D Printing:

Shorten Delivery Times. Parts can typically be shipped within a few days, speeding up design iterations and time to market.

Build Complex Geometry. Allows the creation of unique parts with more complex geometries and precise details without increasing costs.

Reduce Manufacturing Costs. Drive to reduce production costs by eliminating the need for tools and reducing labor.

What is SLA 3D printing?

SLA (stereolithography) 3D printing uses a UV laser to write onto the surface of a liquid thermoset, creating thousands of thin layers until the final part is formed. SLA 3D printing allows for a wide range of materials, very high resolutions, and high quality surfaces.

Advantages of SLA 3D Printing

- Lower layer thickness and higher accuracy.

- Complex shapes and precise details.

- Smooth surfaces and post-processing options.

- Various material property options.

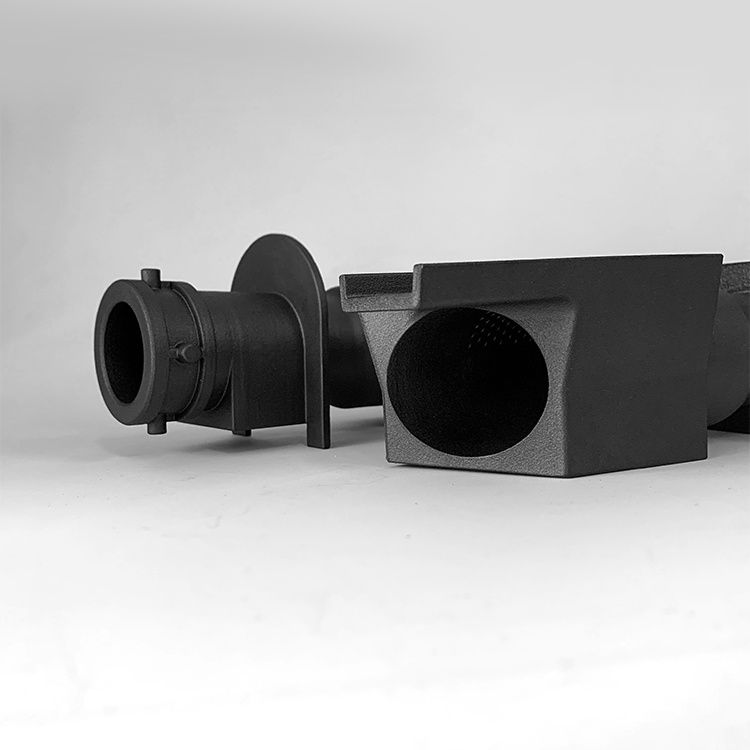

What is SLS 3D printing?

SLS (stereo laser sintering) 3D printing uses a high-power optical laser to fuse small powder particles layer-by-layer to create complex, durable geometric parts. SLS 3D printing builds robust parts with filled nylon material suitable for functional prototypes and end-use parts.

Advantages of SLS 3D Printing

- Engineering-grade thermoplastics (Nylon, GF Nylon).

- Excellent mechanical properties and layer bonding.

- No support structures, enabling complex geometries.

- Temperature resistance, chemical resistance, abrasion resistance.

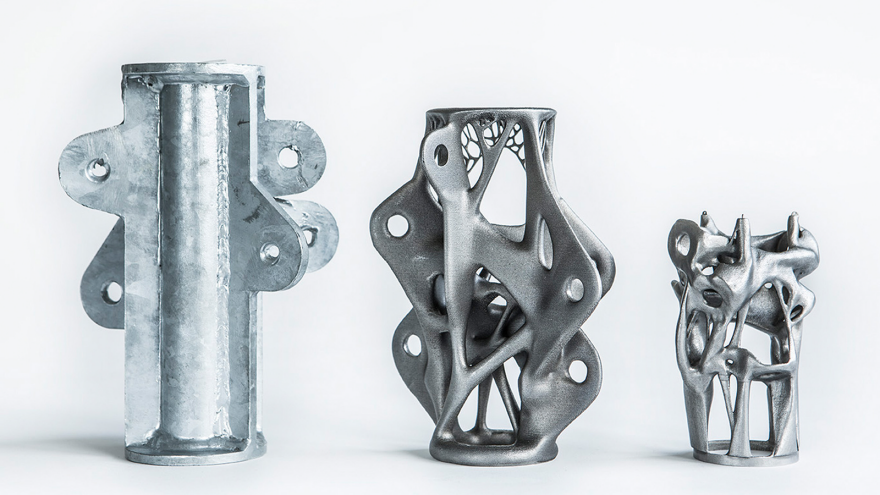

What is SLM 3D printing technology?

SLM (Selective Laser Melting) is an additive manufacturing process specifically designed for 3D printing of metal alloys. Additively create parts by fusing metal powder particles together in a complete melting process.

Why choose SLM 3D printing technology?

The SLM process is of great benefit to anyone who needs to quickly produce metal parts for prototyping or production. It also allows the creation of complex, highly detailed designs that are not possible with other technologies due to the limitations of traditional manufacturing processes.

- Small batches

- Using this technology to get your 3D printed metal part is perfect is particularly adapted if you need to produce small batches.

- Intricate geometries

- This metal 3D printing technology allows you creating thin-walled objects and intricate geometries to get lightweight designs.

- Stress Resistant

- Selective Laser Metal gives you access to materials with great mechanical properties, to create parts handling loads and stress.