Plastic Injection Molding Service

Betly Technologies is a rapidly growing enterprise in industrial area. We can provide you with very precise parts made from our own built-and-maintained moulds. Our costs are unmatched in the industry, and our tooling has some of the best lead times available. Based on your estimated annual needs, we will work closely with you to identify the best tooling material. We'll then provide you comprehensive DFM (Design for Manufacturability) advice to assist you fine-tune your design for the most economically viable parts.

What is DFM?

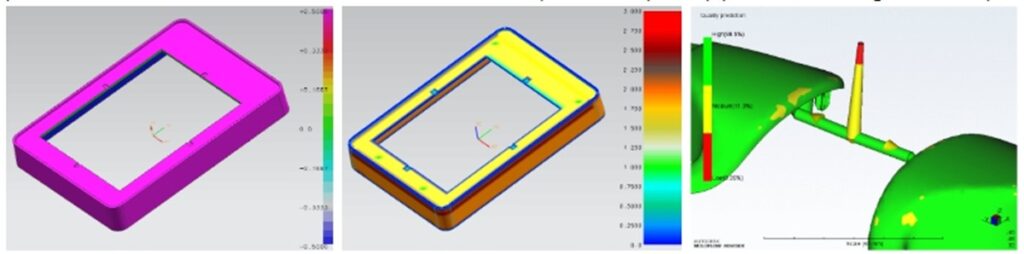

The phrase “Design For Manufacturability” is abbreviated as “DFM.” This means that we carefully examine the 3D CAD files you submit and ensure that your design can be implemented as you intended. After that, we give you a report for each part that lists its specifications (size, weight, material, finish, colour, etc.) and addresses any tooling or part design issues that may have arisen. Furthermore, to assist you in revising the design if necessary, our DFM also contains our ideas on how to best address any problems. You will not be charged for any of our DFM reports’ creation.

Draft analysis

Wall thickness analysis

Gating quality prediction

The Materials of Plastic Injection Molding & Rapid Tooling?

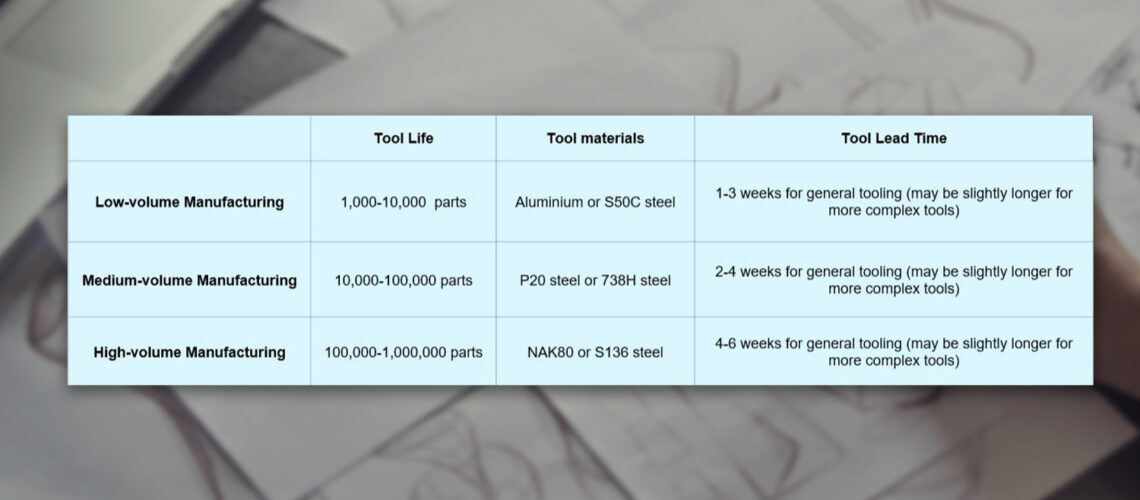

That entirely depends on how many pieces are required. The stronger the tool material must be to withstand wear from repeated moulding cycles, the higher the projected amount. Although every situation is different, the chart below serves as a good place to start when considering what we would suggest for your specific parts:

If I need really high quantities of parts, what steps do you take to assure my parts are as inexpensive as possible?

- We look at many different ways to assure the lowest cost parts possible.

- In order to shorten the cycle time, we use carefully designed cooling systems.

- To satisfy big production capacity and lower part cost, we use multi-cavity tools when appropriate.

- To save labour costs, we frequently employ automatic cutting gates, hook gates, sub gates, and hot tip gates.

Do you have limits on the types of plastics materials you can mold?

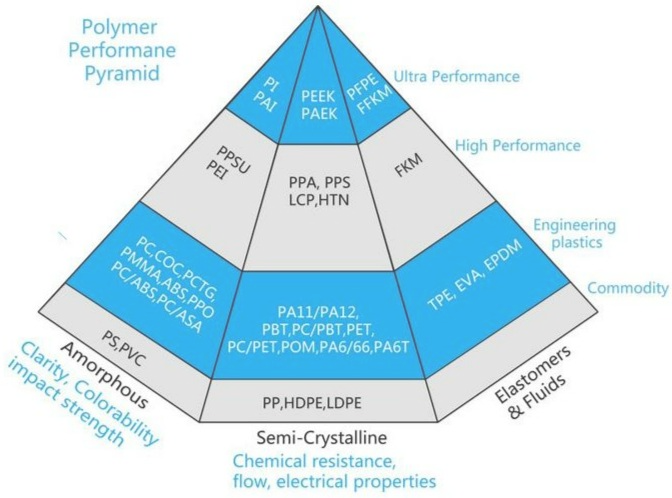

Definitely not. We have the ability to mould a wide range of materials, including low-cost commodity resins like PP, HDPE, and styrene, engineering resins like PC, POM, nylon, and TPE, as well as high-performance materials like PEEK, polyimide, polysulfone, and more. Additionally, we can meet your needs for resins with fibreglass reinforcement.