Vacuum Casting

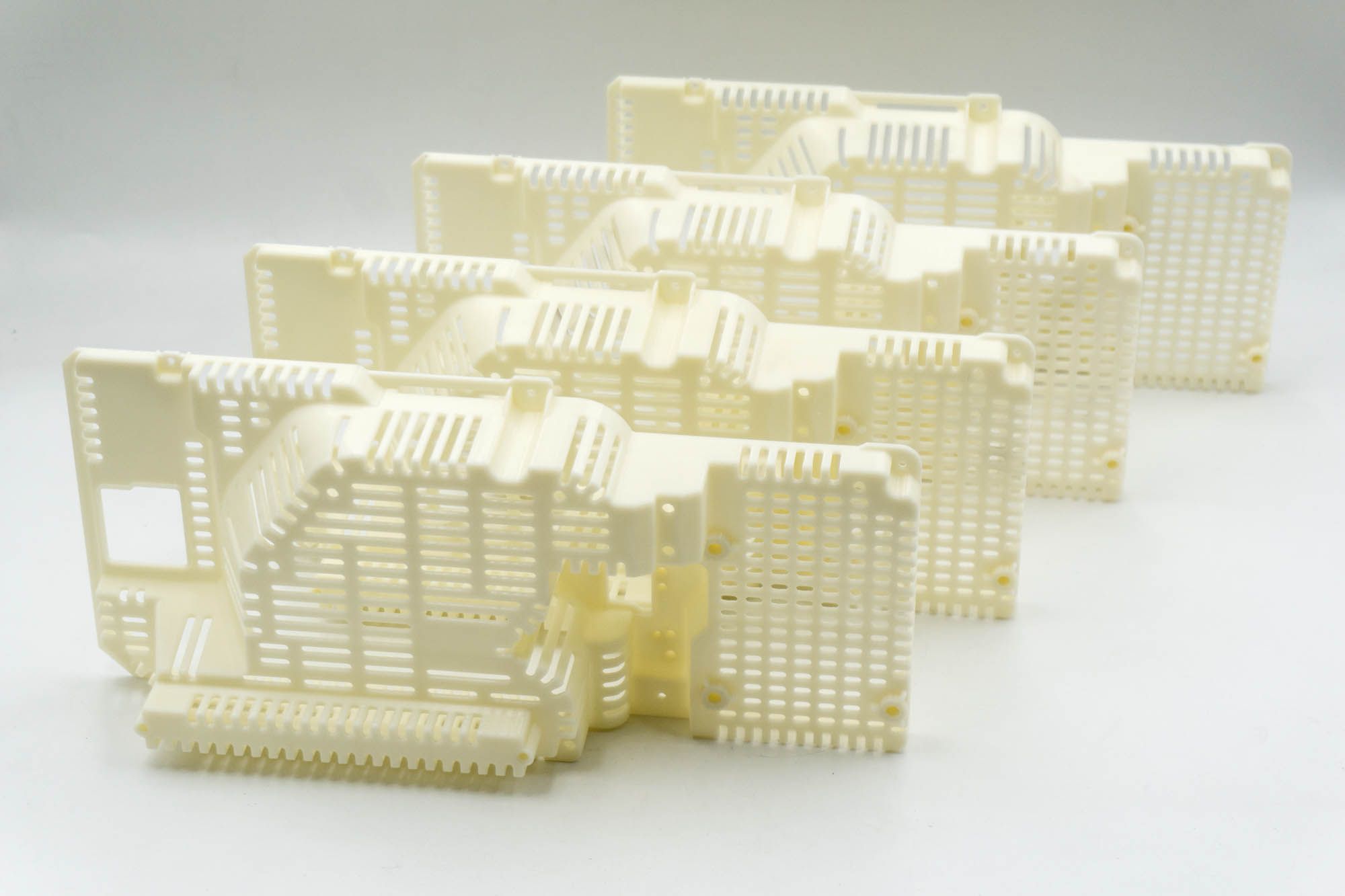

Betly can meet your vacuum casting and silicone molding needs. Our many years of experience in this field enable us to manufacture your plastic parts to the highest standards, cost-effectively and with short throughput times. Vacuum casting is a great way to produce rigid or flexible parts, ideal for high-quality prototyping, functional testing, concept testing, and display demonstrations. Vacuum cast parts can be made from a few to hundreds depending on your needs.

Benefits of Vacuum Casting in Rapid Prototyping

Vacuum casting is one of the most effective rapid prototyping methods used by manufacturers today. It follows a fairly simple manufacturing process and helps manufacturers reduce manufacturing costs. There are many other advantages of molding with rapid prototyping services, which is why many manufacturers use this process as an alternative to injection molding. Benefits include:

- Cost : Vacuum casting allows manufacturers to improve production quality while reducing production Compared to the more expensive plastic injection molding, vacuum forming offers manufacturers many advantages in terms of total production cost. The cost-to-value ratio is great with casting.

- Precision: It is also possible for manufacturers to use vacuum casting machines to create better This process allows for the production of more accurate and precise prototypes that match his delivered 3D designs.

- Complexity: Another advantage of this process is that it allows manufacturers to use vacuum casting machines to prototype more complex designs. By using liquid plastic materials, vacuum casting machines can prototype more complex shapes without worrying about incompatibilities

- Material Options: For the casting process, manufacturers have access to a variety of polyurethane plastic materials. Each polyurethane will have distinctive features that will enable producers to choose the finest products for certain industrial uses.

- Efficiency: It is quite easy to produce prototypes using the casting method, and the plastic materials are easier to work with than their metal counter parts. The ease of production by vacuum casting machine will provide a better efficiency for your prototype production. For the manufacturers, using the casting method can help them produce more prototypes in a shorter production time, while keeping their production costs within their budget.

Vacuum Casting Process

Master Preparing

Your CAD drawings are converted into masters, which are 3D solids. They are typically produced using 3D printing or CNC machining. Making the master in a 40° environment. After finishing and reviewing the masters, we will begin creating silicone mold.

Mold making

Located and firmly placed the master model within a specially sized wooden box. To produce a silicone mould, combine the silicone and pour it into the container. The master is removed from the mould when it has cured

Part Making

The casting resins were poured into the vacant cavity to produce an extremely precise replica of the original. Even overmolding with two or more materials is feasible. Typically, silicone moulds may produce around 20 replicas of the original pattern.

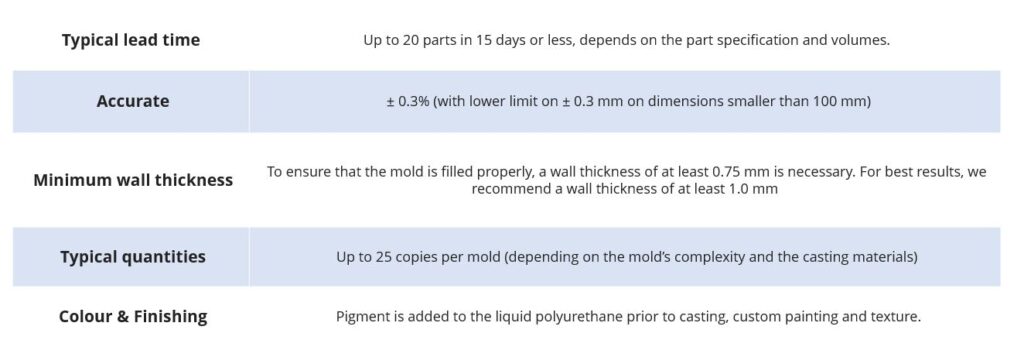

Vaccum Casting Technical Specifications